Molds, Positive or Negative?

Welcome to the Syntec Blog a partial publication where we teach you everything in the field of vacuum forming, also called thermoforming. In this issue we explain the “Positive” as the “Negative” forms.

Sometimes the concepts of positive and negative forms are a bit confusing. Especially if you are not familiar with the vacuum forming process. The following photographs and descriptions cover the main differences between the different types of forms.

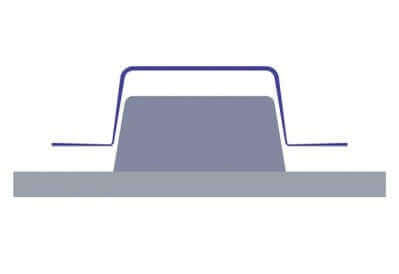

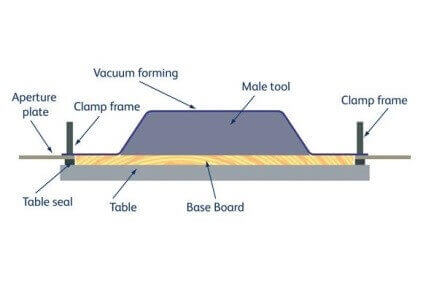

Positive Malformation

Before we show you some examples and tell you why you should use a positive form, we first have to know what it is.

Positive mold formation is a way of thermoforming (vacuum forming) in which the mold sheet is pulled over a master model. This creates a shape above the clamping level of the mold sheet.

Why should I use a positive form?

In positive forms the material flow and the wall thickness of the mold are different than in the case of negative forming. The training costs are often lower with a positive form than with a negative one.

The visible surface of the formed part is usually the upper part of the surface. The thickness of the plastic mold sheet may be able to hide some imperfections on the surface, thereby producing a more attractive surface.

It will be difficult to see some details in a negative mold, such as mother models with deep cavities, a thick bottom and many corners.

Vacuum formation (thermoforming) with positive mold formation.

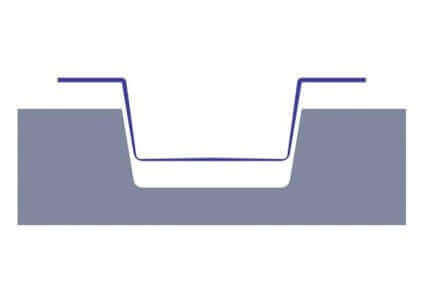

Negative Malformation

Before we show you some examples and tell you why you should use a negative form, we must first know what it is.

Negative forming is a way of thermoforming (vacuum forming) where the shape occurs under the clamping level of the mold sheet. The vacuum-drawn shape does not protrude here above the clamping level of the mold sheet.

Why do I have to use a negative form?

The material flow and the wall thickness of the formed part are different from that of positive forming. If sharp details are required, the bottom of a negative shape can be used as a visual surface. Realizing some small details is not possible with negative vacuum forming.

Shrinkage – The plastic mold sheet will shrink on the sides of the mold sheet. The proper closing of the mold sheet on the vacuum machine ensures savings in material costs.

Vacuum formation (thermoforming) in a negative mold formation.

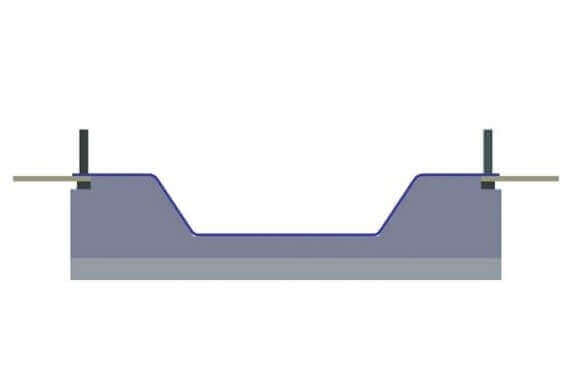

But what if I combine it? Positive model with negative cavities

This is essentially a positive mold that can be used to create negative cavities.

But why do I have to use this way of forming?

You may want to create a negative mold without developing a negative parent model and you do not mind that extra material costs are attached to each cycle. This way of forming uses a positive way of forming combined with negative cavities. This method can be used when negative vacuum forming (position under the clamp) would cause problems.

If you have any questions about the different methods of vacuum forming, or any other question regarding thermofoming, you can always contact us;